PLASTIMIX®

Nucleating and Clarifying Agents

Additive Masterbatches:

Nucleating and Clarifying Agents:

Nucleating agents are sorbitol-based clarifying agents for polypropylene that are used for increasing the transparency in PP moulded products.

Its nucleating activity results in the formation of spherulites (spherical semi crystalline regions inside non-branched linear polymers) that are less than 1 micron in size; this is when non-nucleated products’ spherulites are larger than 20 microns.

This reduction in size brings about improvements in properties of PP including –

* Better transparency

* Better mechanical properties viz., hardness, Tensile strength, elongation, elastic modulus and impact strength

* Higher crystallisation temperature – this results in shorter processing time, faster cycles and therefore higher output and productivity – essentially, lower production cost

PP containing nucleating agent is recommended to be processed at a melt temperature of 230-240 deg. Celsius and with maximum back pressure in the injection moulding machine.

Our nucleating and clarifying masterbatches for Polypropylene give the highest clarity, gloss and smoothness. They can be used in a wide range of PP applications at different temperatures. As they do not affect food stuffs in packaging, they can be used in food contact applications as well.

Third generation sorbitol derivative nucleating agents are used for this masterbatch.

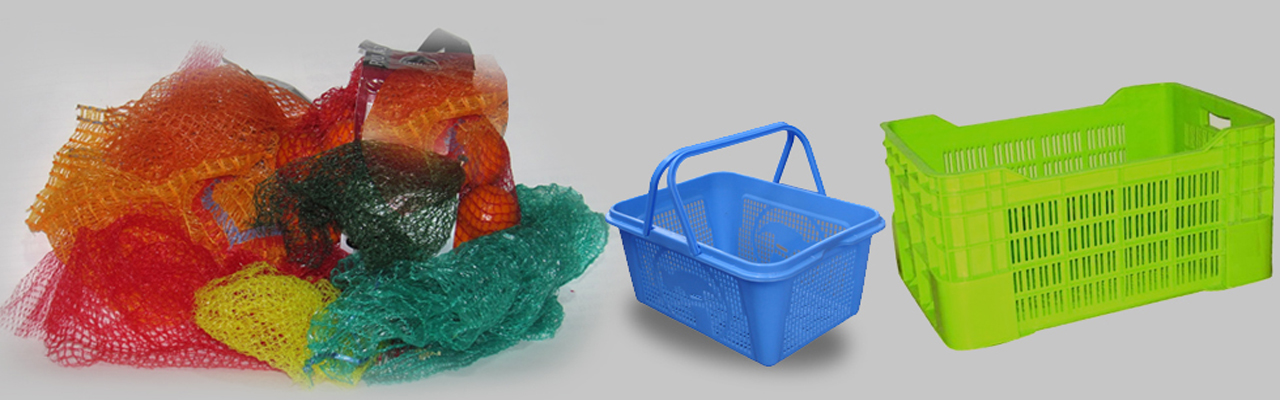

Common applications include Films, PP Moulded products like Disposable syringes, Containers, Buckets, Jugs, Bottles, etc.

Nucleating Agent Masterbatches offered by Sri Vasavi Pigments (P) Ltd.

|

Product Name / Code |

Carrier Resin |

Active Ingredient |

Application |

LDR |

Advantages |

|

NUCLEATING AGENT MB 01 (SV 91B001 NU) |

PP |

10% |

Films, PP Moulded products like Disposable syringes, Containers, Buckets, Jugs, Bottles etc.

|

1% - 2% |

Increasing the transparency of the product. |

|

NUCLEATING AGENT MB 02 (SV 91B002 NU) |

PP |

12% |

Same as above |

1% - 2% |

Same as above |

|

C LARIFYING AGENT MB 01 (SV 91B001 CA) |

PP |

10% |

Same as above |

1% - 3% |

Same as above |